SPECIFICATIONS

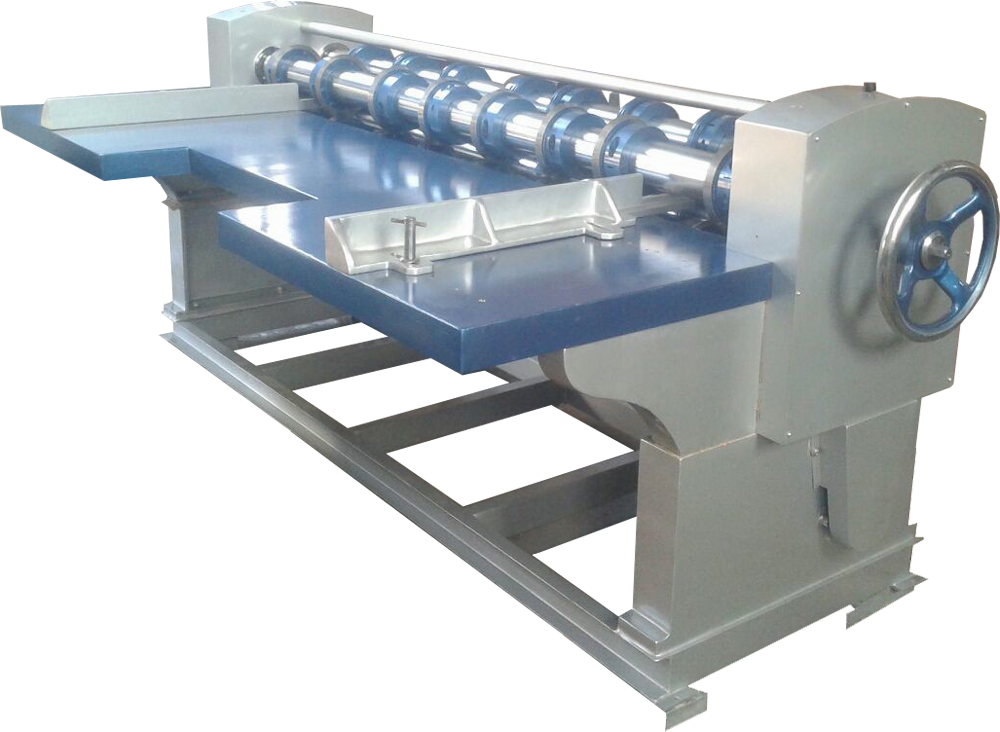

- Design Speed : 200 ft. (min)

- Effective width : 1400 mm – 2200 mm

- Corrugated roller : f128 mm

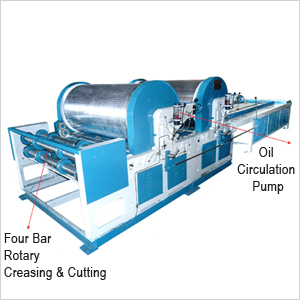

- Drive reducer box with oil immersed type lubricating to reduce noise keep running stable adopt gimbal transmission. separate power.

- Corrugating roller, pressure roller & glue roller by pneumatic adjustment.

- Cardboard transmit adopt vacuum suction method, with wind control system. keep flute profiles stable of the lower-roller in the condition of running up.

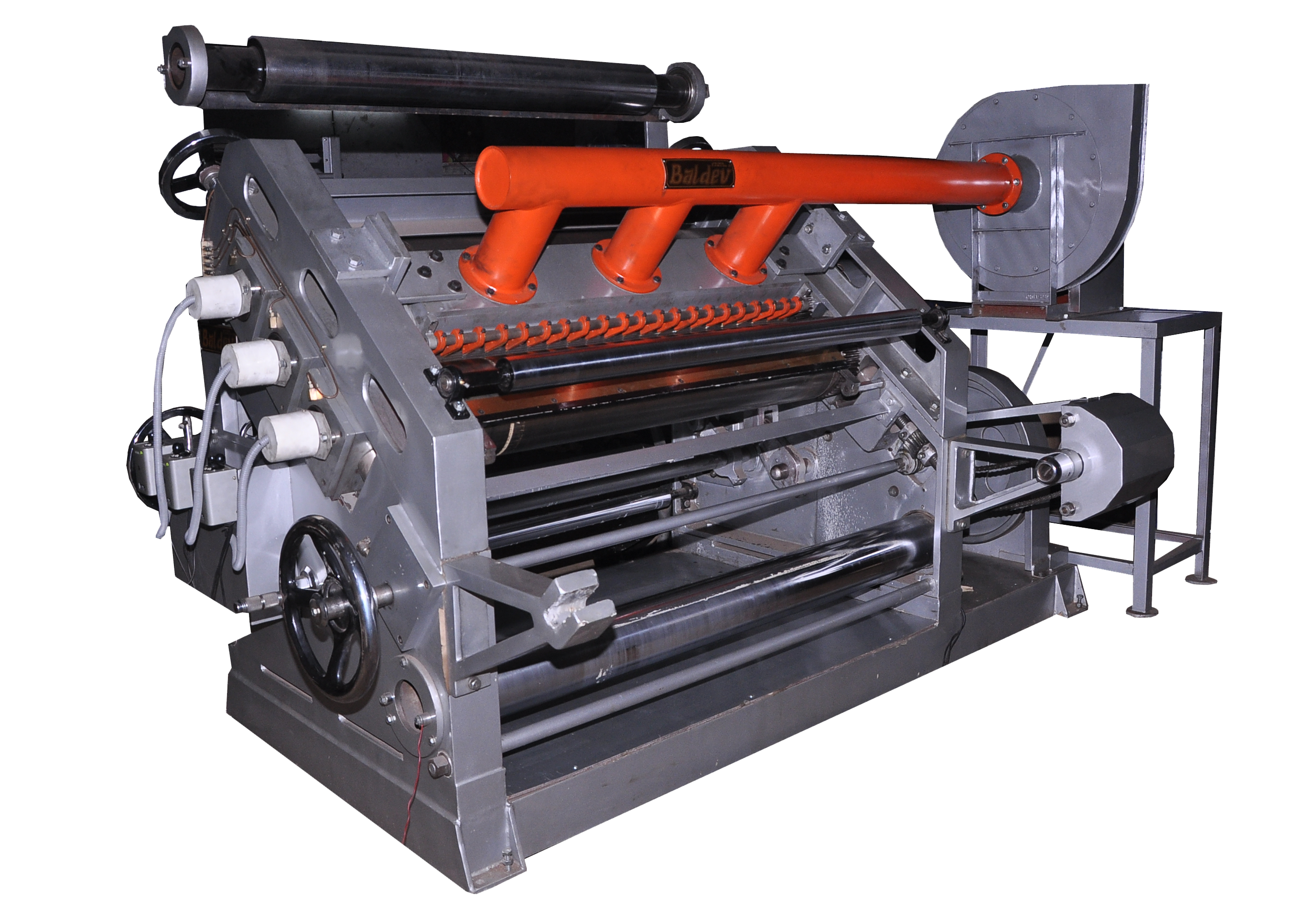

- Bearing of corrugated & pressure roller adopt high temperature lubricate grease.

- Gule parts auto supply gule circularly.

- The upper-lower corrugating roller are made of 48CrMo high quality alloy steel, after heat-treatment. The hardness HRC580-600, the surface be grined.

- The gule part surface are treated by special mesh snicked & chromeplated.

- Motorized or manual glue width dividing to match the paper width.

- Glue part can be running independently or non-independentle while stopped. Adopt main motor frequency conversion control. (Optional)